Home > Solution

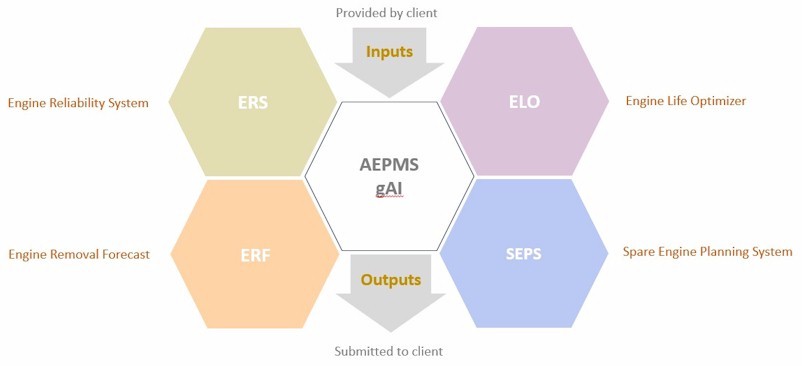

Four integrated, yet independent systems provide a complete solution |

The Spare Engine Planning System not only determines

the number of spare engines needed to support your air operations, but also specifies the proper allocation of engines

throughout your operation network. In addition, you can use SEPS to decide how many engines to stock at the base and

maintenance stations for a given number of spares, and what protection levels and fill rates can be expected at different

stations for various allocation scenarios. |

|

|

View AEMPS data flows and existing system interfaces. (Click here) |

|

You can work in Microsoft Excel for data entry and editing. This substantially eases data handling. In addition, often the data required by AEMPS exists in MS Excel from various sources. As such, data-entry duplication is avoided by using the facilities of MS Excel. |

|

AEMPS output reports are also exported to, and transmitted in, MS Excel. That way, custom-built reports can be developed. Also, further analyses of AEMPS output reports, including creating graphical charts, and/or making the results available for other applications, can be done easily because of this data export facility to MS Excel. |

|